Assembly & Project Management

Many of our customers’ jobs require Planet Products Corporation’s project management expertise to bring a number of components and processes together into a final turn-key assembly. Planet manages sub-contractors to handle Nadcap and/or Customer-Approved sources for any number of outside processes. These include heat treat, stress relieve, coatings, painting, non-destructive testing, welding, etc. Our skilled assembly team integrates machined components with commercial electronics, gears, fittings, lubricants, and gaskets. Sealed assemblies can be tested in-house up to 3800psi.

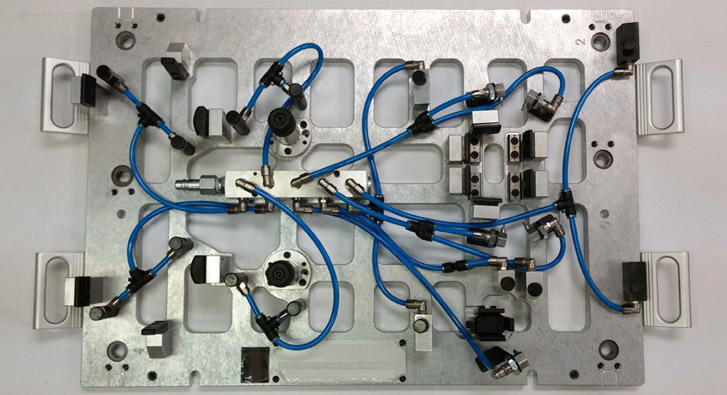

Example Past Projects

- Armored vehicle turret manual traverse and elevation gear boxes

- Hydraulic motors for commercial and defense applications

- Hydraulic valves

- Complex fixtures for factory test equipment

Subcontract Process Management (Nadcap and/or Customer-Approved Sources)

- Heat Treat

- Stress Relieve

- Coatings

- Painting

- Non-Destructive Testing

- Welding

Print This Page

Print This Page