Multi-Axis Milling

Planet Products Corporation utilizes numerous CNC mills, with our largest machine capable of handling parts up to 64" x 32" x 30". The majority of machined tolerances are .005” or less and we regularly machine parts with even tighter features. Many features include large and small bores, deep hole drilling, thread milling and tapping, intricate pockets, and ribs that require significant attention to detail in order to avoid error stack-up.

Example Past Projects

- Manifolds for Defense and Commercial Systems

- Structural Components

- Robotics

- Casings

- Brackets and Frames

- Fixtures

- Bearing Caps

Any Material Type

- Forgings and Castings

- Blocks, Plates, Bars, Extrusions

- Aluminum Alloys

- Titanium

- Steel Alloys

- Nickel Alloys

- Cobalt

- Ductile Irons

- Plastics

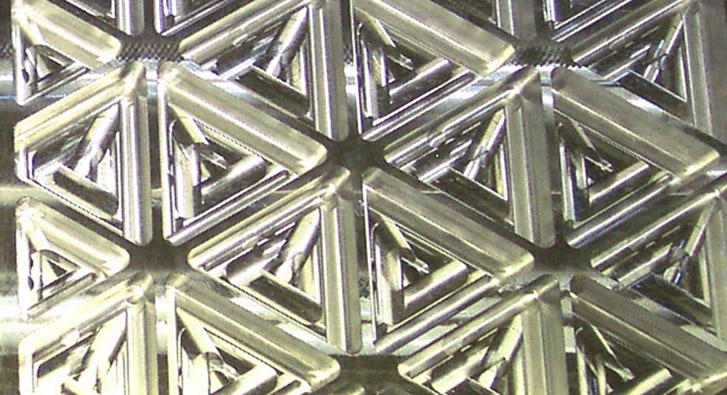

Aluminum, milled from a single piece of material. Requires significant attention to detail and precision machining to avoid error stack-up between ribbed features.

Precision bore and threaded holes on aluminum manifold. Deep hole drilling and multiple large bores with “blind” intersections located internally.

Print This Page

Print This Page